|

|

Stones are understood to be hard in nature but before a customer get's his first hands on them, they have been subjected to harsh treatment as they travel miles through rough seas. Hence it is fundamental & essential that they are securely packed to surpass all the harsh treatment.

We as a manufacturer and processors of stones give value to our production and hard work of workers, we would not like that our stones break away while in transit. In order to protect these stones from breakage or even damage (like staining, etc.) our dedicated packaging team ensures the right procedures while packing stones in wooden crates.

|

| |

|

|

Each wooden crate is first inlined with polythene to protect stones from staining from wooden planks or from any other feature, then it is inlined with foam-sheet along horizontal planks to protect stones against damage from wooden planks or nails. This is a fundamental preliminary packing used for all our wooden crates irrespective of the type of stone packed. Each wooden crate is first inlined with polythene to protect stones from staining from wooden planks or from any other feature, then it is inlined with foam-sheet along horizontal planks to protect stones against damage from wooden planks or nails. This is a fundamental preliminary packing used for all our wooden crates irrespective of the type of stone packed. |

| |

|

|

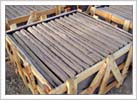

In case of outdoor stones like flagstones, landscaping stones, circles, etc which are basically rough stones, they are directly stacked in the wooden crates. Any loose gaps are tightened with filling material like wood, hardboard, foamsheet, etc to protect stone slabs/tiles from colliding with each other. In case of outdoor stones like flagstones, landscaping stones, circles, etc which are basically rough stones, they are directly stacked in the wooden crates. Any loose gaps are tightened with filling material like wood, hardboard, foamsheet, etc to protect stone slabs/tiles from colliding with each other. |

| |

| Packaging of polished tiles |

|

|

In case of polished stones, surface of each slab/tile is protected by using a paper cloth or 2mm-foam while tightly stacking them in a wooden crate. This protects the polished surface of stones from scratching due to abrasion of dust particles between two tiles. In case of polished stones, surface of each slab/tile is protected by using a paper cloth or 2mm-foam while tightly stacking them in a wooden crate. This protects the polished surface of stones from scratching due to abrasion of dust particles between two tiles. |

| |

| Packaging of thinner tiles |

|

|

In case of 10mm or 15mm tiles which are very thin to break, 6-10 such tiles are first packed in cardboard boxes. These boxes are then tightly stacked in the wooden crate. Cardboard boxes provide additional cushion to the thin tiles and prevent them from breakage. In case of softer but costlier stones like polished marble or granite tiles in 10mm thickness, 5-10 such tiles are first packed in Styrofoam (thermocol) boxes and then tightly stacked in wooden crate. In case of 10mm or 15mm tiles which are very thin to break, 6-10 such tiles are first packed in cardboard boxes. These boxes are then tightly stacked in the wooden crate. Cardboard boxes provide additional cushion to the thin tiles and prevent them from breakage. In case of softer but costlier stones like polished marble or granite tiles in 10mm thickness, 5-10 such tiles are first packed in Styrofoam (thermocol) boxes and then tightly stacked in wooden crate. |

| |

|

|

In case of mint sandstone, specially, it retains moisture and is off-white to peach-yellow in color. The 15mm tiles as mentioned above are packed in cardboard boxes but thicker tiles with pencil edge, bullnose or rebated bullnose are individually packed in polythene bags before tight stacking in wooden crates. As a special case the wooden crates are also inlined with thermocol sheets for additional protection. We have adopted this special packing method with our experience. In case of mint sandstone, specially, it retains moisture and is off-white to peach-yellow in color. The 15mm tiles as mentioned above are packed in cardboard boxes but thicker tiles with pencil edge, bullnose or rebated bullnose are individually packed in polythene bags before tight stacking in wooden crates. As a special case the wooden crates are also inlined with thermocol sheets for additional protection. We have adopted this special packing method with our experience. |

| |

|

|

We offer option of customized packaging to our customers. At the time of order placement, customers can ask us for any specialized or customized packing requirements which will be duly fulfilled to the best capacity. We continuously strive to further improve our packaging methods as we learn from our customers. We welcome feedback from all customers. We understand that the cost of packing is minimal against the cost of stones and customer satisfaction. Our quality of packing directly reflects the quality of stones we produce. We offer option of customized packaging to our customers. At the time of order placement, customers can ask us for any specialized or customized packing requirements which will be duly fulfilled to the best capacity. We continuously strive to further improve our packaging methods as we learn from our customers. We welcome feedback from all customers. We understand that the cost of packing is minimal against the cost of stones and customer satisfaction. Our quality of packing directly reflects the quality of stones we produce. |

| |

|

|

Large quartzite and granite slabs are securely stuffed in our factory in wooden pallets. Large quartzite and granite slabs are securely stuffed in our factory in wooden pallets. |

| |

|

| |